Computational techniques give scientists powerful ways to understand and design materials. They combine mathematics, simulation, and artificial intelligence to predict outcomes before large-scale testing. These computational approaches support research across alloys, ceramics, coatings, and composites. They also connect theoretical concepts with practical engineering results.

Artificial Intelligence in Materials Science

Artificial intelligence methods can capture complex relationships in data. Neural networks, for instance, learn patterns between chemical composition and material properties. One study applied these models to magnesium alloys and achieved reliable predictions of hardness and strength. Genetic algorithms and expert systems provide additional ways to explore solutions when many variables interact. As a result, researchers save time by limiting the need for repeated experiments.

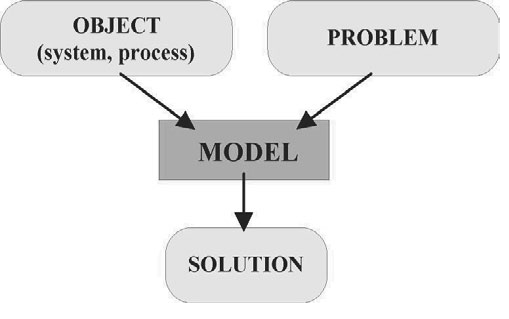

This figure illustrates the conceptual framework for applying AI to materials research.

Virtual Environments and Design Tools

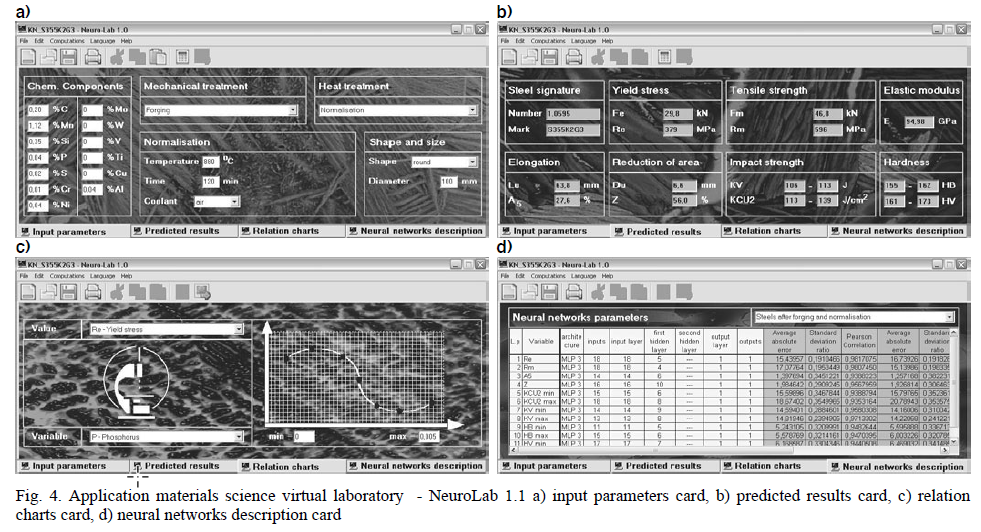

Computational design environments allow scientists to test multiple scenarios. A virtual laboratory can simulate how different materials behave without preparing every sample physically. This approach accelerates discovery and enhances education, as students can explore material behavior in interactive settings. Computer-aided design systems add further support by suggesting optimal materials and processing routes. Databases of properties strengthen these tools by offering reference values for comparison.

This figure shows how input data, predictions, and relations are presented in a virtual lab environment.

Numerical Methods and Simulations

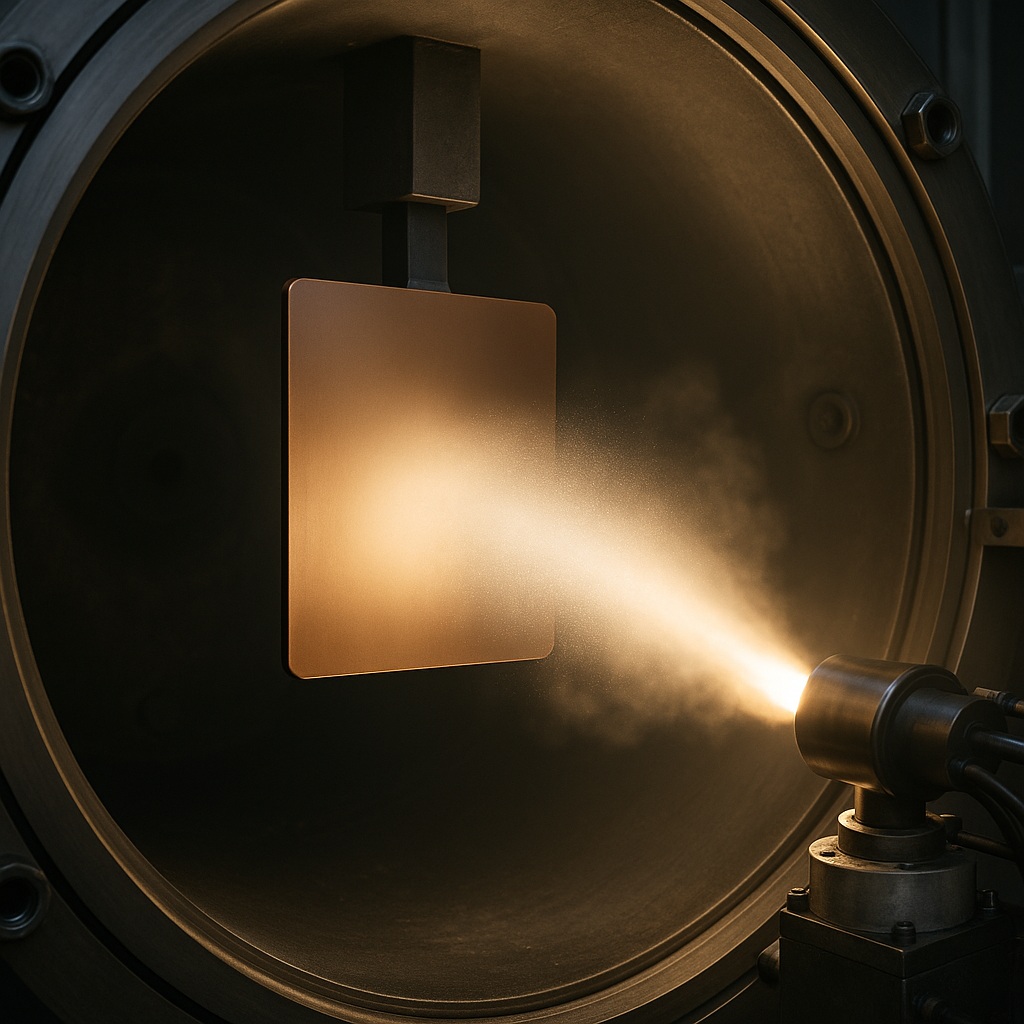

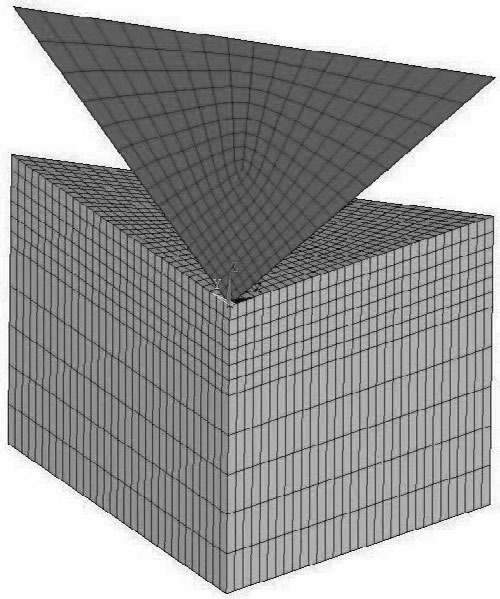

Beyond artificial intelligence, numerical approaches remain vital. Finite element analysis is widely used to simulate stresses, strains, and hardness in coatings. For example, researchers modeled how PVD films respond to indentation. The results showed stress distributions that matched experimental data. Such simulations demonstrate that digital methods can reproduce laboratory outcomes with accuracy. They also highlight how computation helps explain microstructural effects on performance.

This figure illustrates the numerical setup used to predict stresses and deformation in thin films.

Integration of Methods

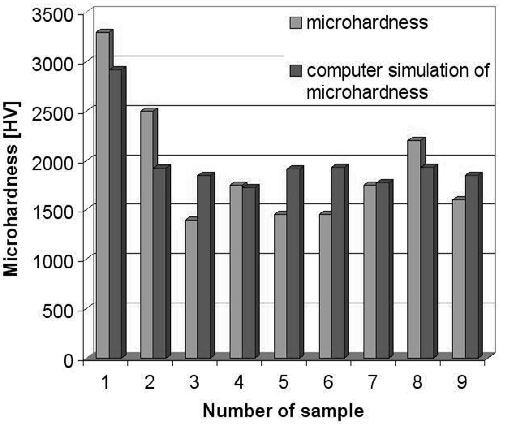

Modern studies often combine AI with numerical modeling. By linking data-driven approaches to simulations, researchers can predict both overall trends and local behavior. This integration strengthens reliability and provides more profound insight. Engineers now use these methods to design alloys, improve surface treatments, and evaluate long-term durability. Consequently, computational science has become a bridge between laboratory work and industrial application.

This figure demonstrates how computational predictions align with experimental validation, highlighting the strength of combined approaches.

Computational approaches, therefore, shape progress in materials engineering. They reduce cost, improve precision, and expand opportunities for both research and teaching.