Overview

Engineering materials form the foundation of modern technology. They are designed and selected for strength, durability, and specific functions. For example, alloys, ceramics, composites, polymers, and biomaterials are studied to create new solutions for industry, medicine, and advanced technologies.

Metallic alloys remain among the most critical groups of engineering materials. They combine elements to improve mechanical behavior, corrosion resistance, and reliability. In addition, ceramics and glasses provide hardness, heat resistance, and chemical stability. Polymers offer versatility and lightweight structures, while composites and nanostructured materials combine different phases or scales to enhance performance. Biomaterials extend the field into medical use. Finally, multifunctional and innovative materials add responsiveness to external conditions.

Magnesium Alloys

A notable example of engineering materials is magnesium-based alloys. They are valued for low density, high strength-to-weight ratio, and potential in lightweight structures. Therefore, they are applied in automotive, aerospace, and electronic devices, where reducing mass improves efficiency.

The performance of magnesium alloys depends strongly on composition and processing. As a result, properties such as hardness, ductility, and corrosion resistance vary with alloying elements. Predicting these properties accurately is essential for design and application.

Computational Approaches to Alloys

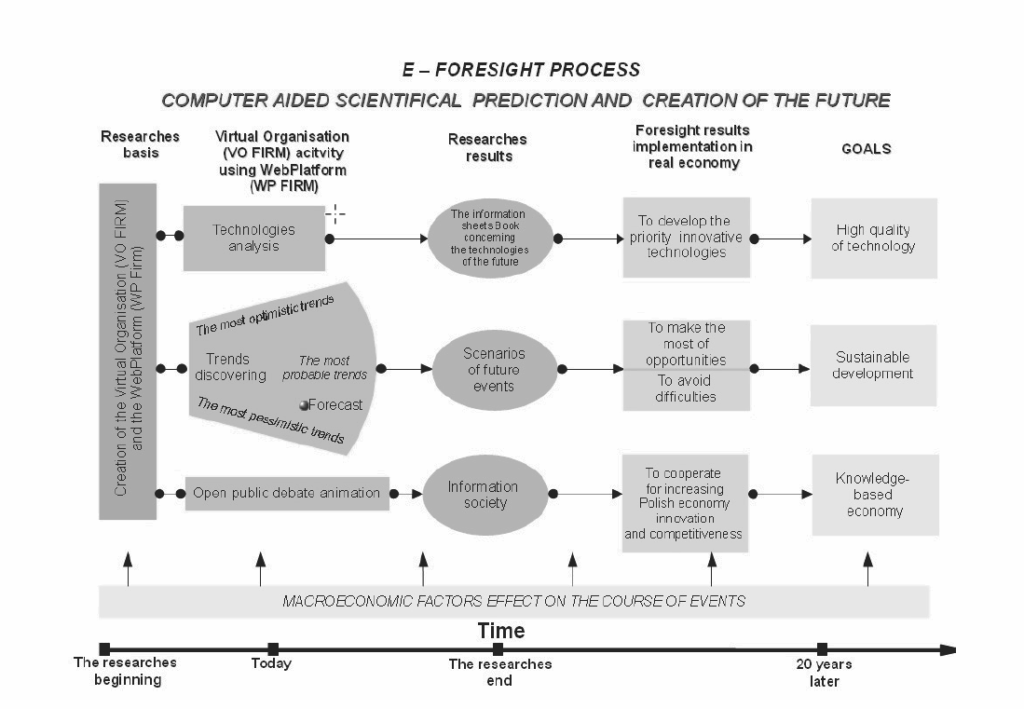

Results showed that computational tools can forecast behavior without extensive physical testing. This approach supports faster design and optimization of alloys.

One study applied artificial neural networks to predict the mechanical properties of Mg-Al-Zn alloys. The models analyzed relationships between alloy composition and resulting characteristics. In this way, computational tools forecast behavior without extensive physical testing. Thus, they support faster design and optimization of alloys.

Moreover, such computational methods highlight the connection between material science and data analysis. By modeling input variables, researchers reduce experimental time and cost. For magnesium alloys, this means more efficient development of lightweight and durable materials.

Conclusion

Engineering materials include metals, ceramics, composites, polymers, and emerging innovative systems. Magnesium alloys illustrate how material properties influence applications in critical industries. Overall, combining experimental research with computational modeling enhances understanding and accelerates progress. These efforts expand knowledge and enable the creation of materials with improved performance.