Understanding material properties is essential for predicting performance and ensuring reliability. Properties such as ductility, fatigue resistance, creep resistance, and fracture toughness define how materials behave under stress. Other important aspects include corrosion resistance, electrical behavior, and magnetic response. These factors determine whether a material is suitable for a given environment or application.

Mechanical and Physical Behavior

Mechanical tests reveal how materials resist force and deformation. Ductility shows how a sample stretches without breaking, while hardness measures resistance to indentation. Fatigue and creep describe long-term changes under repeated or sustained loads. In addition, electrical and magnetic properties influence the use of materials in energy systems, sensors, and electronics.

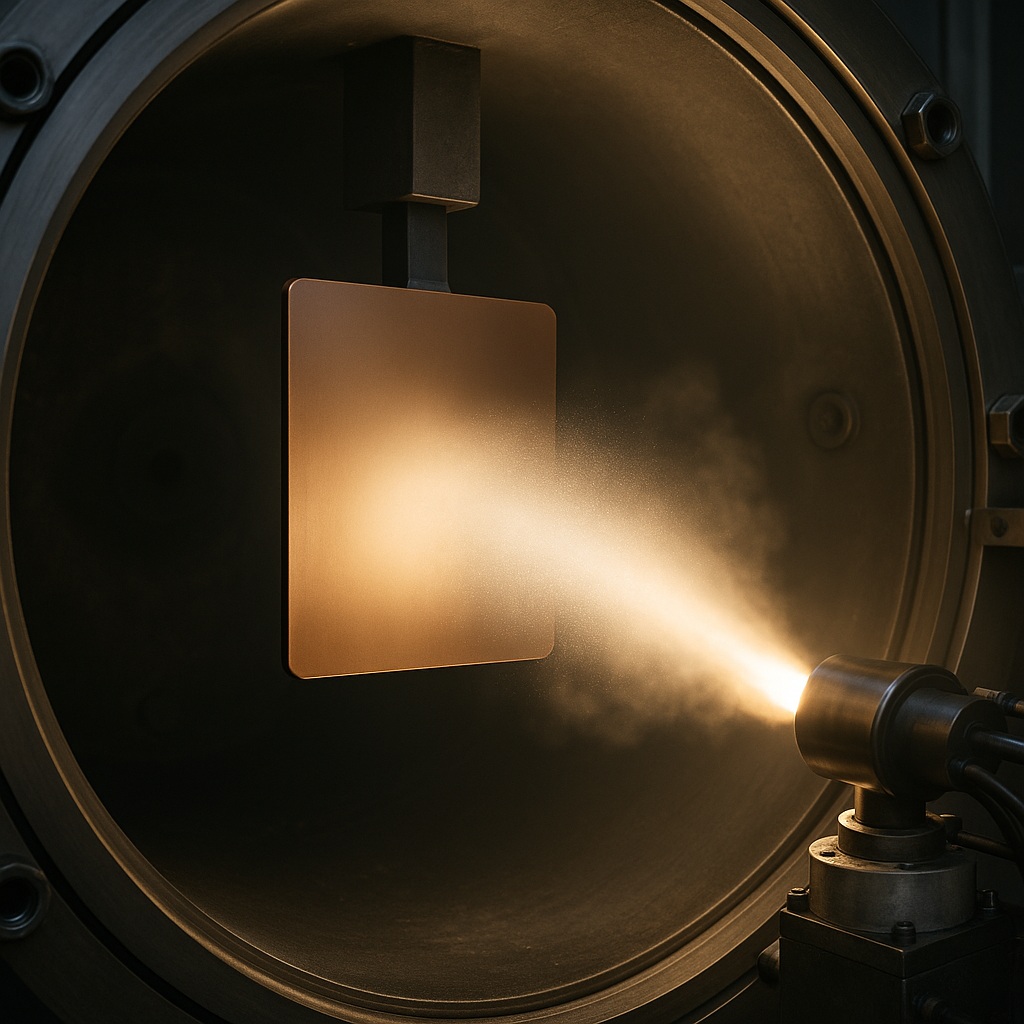

This figure supports the discussion of mechanical behavior by showing how stresses relate to substrate conditions.

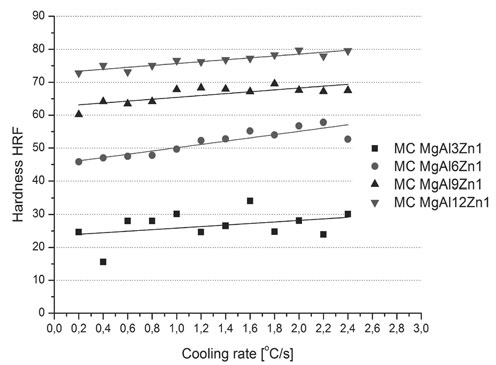

Microhardness and Stress Analysis

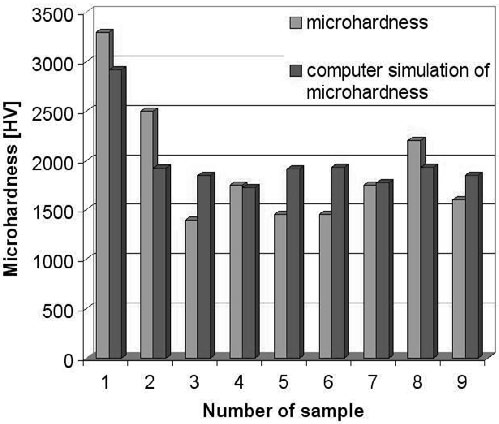

Research on physical vapor deposition (PVD) coatings illustrates the importance of surface properties. Scientists studied TiN and TiC films deposited on high-speed steel. They used finite element methods to model how an indenter interacts with the coating. The analysis produced stress maps and hardness values. Later, researchers compared those results with laboratory tests and confirmed accuracy. This example shows how computational methods complement experiments.

This figure visually demonstrates how simulation results align with experimental data. It emphasizes the reliability of computational methods in predicting material properties.

Corrosion, Wear, and Reliability

In service, materials often face harsh operating environments. Corrosion and wear gradually reduce strength and surface quality. Performance depends on composition, processing, and microstructure. Therefore, engineers assess reliability through non-destructive testing and long-term monitoring. These methods help confirm safety while reducing the need for destructive evaluation.

Characterization Techniques

Advanced tools connect structure with properties. Electron microscopy reveals grain boundaries and defects. X-ray diffraction shows phase composition, while spectroscopy identifies chemical bonds. Image analysis and quantitative materialography describe microstructural patterns. Consequently, these techniques build a clear link between microscopic features and macroscopic performance. Material properties research connects processing, structure, and function. By combining experiments with simulations, engineers improve their understanding and predict outcomes more effectively. As a result, they design materials that meet industrial, technological, and environmental requirements.